precious metals casting production equipment

what we offer

Production technology for gold casting, silver casting and their alloys.

Mint, Jewellery, Electronics & Dental industry applications.

Horizontal and vertical downward continuous casting equipment for casting precious metals.

Batch casting capability from 0.5 kg (16 oz).

Continuous casting up to 1,000 kg/hr (32,000 oz/hr).

Equipment for: wire rod from 4mm

large billet up to 200 mm dia.

strip from 10mm up to 400mm wide

special shapes, e.g. trapezoid for sputtering targets

ingot shape for 1,000 oz bars

Customers for precious metals include: Royal Canadian Mint; Sunshine Minting Inc.; Shanghai Mint; The Perth Mint; Sempsa JP; Leach Garner & Academy Precision Materials.

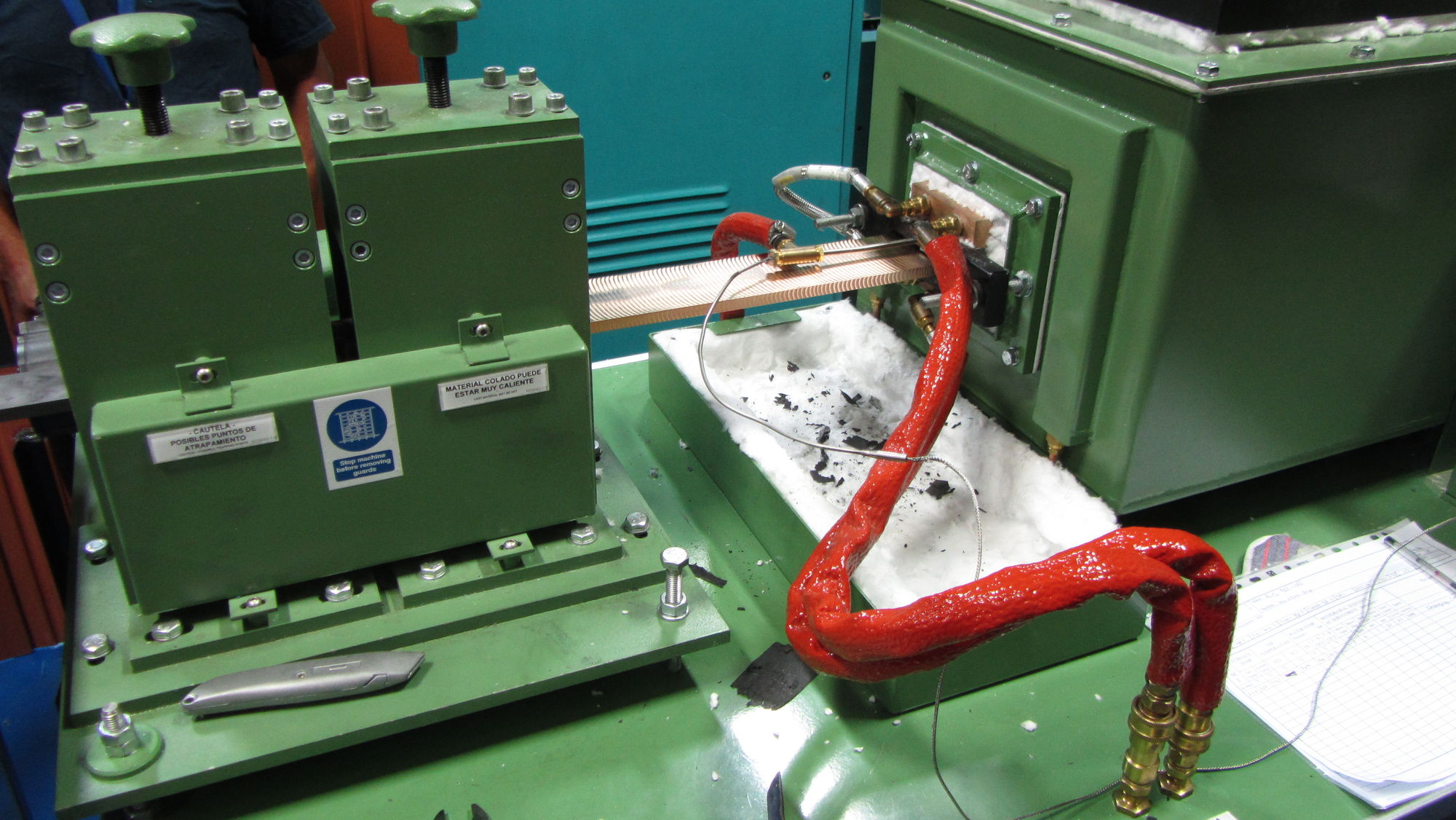

Examples of Rautomead technology for production of gold & silver and their alloys

|

|

| RT 650 silver billet | Coiler for silver & gold strip |

|

|

| RVS III for gold strip | Gold billets 80mm dia. |

features

- Controls system Omron, Siemens or Allen Bradley.

- Repeatability of production using programmes stored in and recalled from menu system.

- High-tech cooler and graphite casting die tooling design.

- Graphite crucible & resistance heating.

- Precise control of withdrawal extraction pulse movement.

- Data recording for quality control

- Range of in-line cutting and handling options: bandsaw, circular saw & coilers according to requirements.

The following global companies trust us in precious metals

|

|

|

| Royal Canadian Mint | Sunshine Minting Inc | The Perth Mint |

All Rautomead installations reference list – Precious Metals & Mints 1984 - 2024